Remove the pipe pump

Introduction

introduction

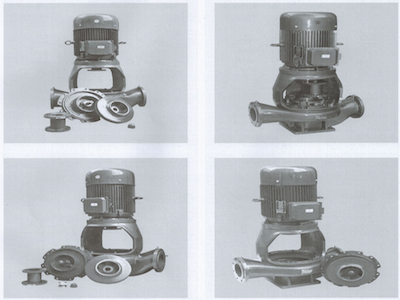

100% of the demolition of the structure to solve the replacement of high-power pump bearings, mechanical seals, impeller, pump shaft problems

product description:

YAGB The vertical pump, especially in the overall structure of the bold breakthrough design, the use of independent bearing body, pump shaft support, to solve the original vertical pump by the motor shaft support shortcomings; impeller, pump with the most modern water Force model design and manufacture, eliminating the original vertical pump axial force of the shortcomings of the motor using Y series of standard general motor to solve the original vertical pump extension shaft motor supporting the difficult problem of replacement; while 100% of the demolition structure to solve The replacement of high-power pump bearings, mechanical seals, impeller, pump shaft problems. The pump compared with similar domestic products, with a more stable operation, long service life, supporting more convenient, easier maintenance and other irreplaceable advantages. In the vertical pump products in the domestic initiative, the technology Habitat leading domestic, is the best alternative to conventional centrifugal pump products.

The main purpose:

YAGB-type removable pipe pump is mainly used for industrial, urban high-rise building water supply, fire pipe pressurization, HVAC hot and cold water circulation, long-distance water supply and production process cycle pressurized transport. YARGB type folding single-stage hot water pump: for metallurgical, chemical, textile, wood processing, paper and hotels, bathrooms, hotels and other high-temperature hot water boiler cycle and urban heating system heating pump.

High-rise building pressurized water

2. Factory system delivery

3. Water treatment system pressurized

4. Central air conditioning hot and cold water cycle

5. Boiler system delivery

6. Swimming pool water supply

7. In the process of pressurization cycle.

Conditions of Use:

Liquid temperature -15 ℃ ~ +120 ℃.

Working pressure, the maximum working pressure ≤ 1.6MPa, that is, the system pressure = inlet pressure + pump head work pressure ≤ 1.6MPa; the ambient temperature does not exceed 40 ℃, the ambient humidity does not exceed 95%; suction liquid for water or similar Water liquid, the solid insoluble volume does not exceed 0.1% per unit volume, particle size ≤ 0.2mm.

Features

1. Vertical structure, easy installation and commissioning, unique design of the motor and the pump body with a joint connection, high concentricity, high precision, covers an area of greatly reduced, reducing the construction investment. Stable, compact, beautiful Casting and appearance treatment to give a new centrifugal centrifugal beauty.

2. Equipped with the famous domestic manufacturers of low-speed Y series standard universal motor, running smoothly, the noise is very low.

3. Bearing the use of international famous brand precision bearings, high precision, good reliability, long life

4. Impeller with the current self-balancing axial force of the hydraulic model, making the pump bearings and mechanical seal life greatly extended.

5. Bearings within the motor bearing are equipped with oil holes and oil hole, the bearing maintenance is very convenient.

6. Removable claw-type flexible coupling, the pump start without vibration, no noise, rotating parts with a reliable security shield, excellent security.

7. Mechanical seal made of stainless steel, silicon carbide, fluorine rubber and other materials, high temperature, high pressure, long operating life, no leakage, no wear on the shaft to ensure that the working environment clean and tidy.

8. Pump cover structure design is unique, as long as the removal of claw-type elastic coupling, pump nut, you can very light out of the bearing, pump cover, pump shaft, impeller and other components, to replace the mechanical seal and impeller, Remove the motor, pump and pipe, easy maintenance.

Type no. | Flow quantity Q | lift m | speed r/min | The motor power KW | |

m3/h | l/s | ||||

15-80 | 1.5 | 0.42 | 8 | 2800 | 0.18 |

20-110 | 2.5 | 0.69 | 15 | 2800 | 0.37 |

20-160 | 2.5 | 0.69 | 32 | 2900 | 0.75 |

25-110 | 4 | 1.11 | 15 | 2900 | 0.55 |

25-125 | 4 | 1.11 | 20 | 2900 | 0.75 |

25-125A | 3.6 | 1.0 | 16 | 2900 | 0.55 |

25-160 | 4 | 1.11 | 32 | 2900 | 1.5 |

25-160A | 3.7 | 1.03 | 28 | 2900 | 1.1 |

32-100 | 4.5 | 12.5 | 12.5 | 2900 | 0.55 |

32-100(I) | 6.3 | 1.75 | 12.5 | 2900 | 0.75 |

32-125 | 5 | 1.39 | 20 | 2900 | 0.75 |

32-125A | 4.5 | 1.25 | 16 | 2900 | 0.55 |

32-160 | 6.5 | 5 | 32 | 2900 | 1.5 |

32-160A | 4 | 1.1 | 25 | 2900 | 1.1 |

32-160(I) | 6.3 | 1.75 | 32 | 2900 | 2.2 |

32-200 | 4.5 | 12.5 | 50 | 2900 | 3 |

32-200(I) | 6.3 | 1.75 | 50 | 2900 | 4 |

32-200A | 4 | 1.11 | 44 | 2900 | 2.2 |

40-100 | 6.3 | 1.75 | 12.5 | 2900 | 0.55 |

40100A | 5.6 | 1.56 | 10 | 2900 | 0.37 |

40-125 | 6.3 | 1.75 | 20 | 2900 | 1.1 |

40-125A | 5.6 | 1.56 | 16 | 2900 | 0.75 |

40-160 | 6.3 | 1.75 | 32 | 2900 | 2.2 |

40-160A | 5.9 | 1.64 | 28 | 2900 | 1.5 |

40-160B | 5.5 | 1.53 | 24 | 2900 | 1.1 |

40-200 | 6.3 | 1.75 | 50 | 2900 | 4 |

40-200A | 5.9 | 1.64 | 44 | 2900 | 3 |

40-200B | 5.3 | 1.47 | 36 | 2900 | 2.2 |

40-250 | 6.3 | 1.75 | 80 | 2900 | 7.5 |

40-250A | 5.9 | 1.64 | 70 | 2900 | 5.5 |

40-250B | 5.5 | 1.53 | 60 | 2900 | 4 |

40-100(I) | 12.5 | 3.47 | 12.5 | 2900 | 1.1 |

40-100(I)A | 11 | 3.05 | 10 | 2900 | 0.75 |

40-125(I) | 12.5 | 3.47 | 20 | 2900 | 1.5 |

40-125(I)A | 11 | 3.05 | 16 | 2900 | 1.1 |

40-160(I) | 12.5 | 3.47 | 32 | 2900 | 3 |

40-160(I)A | 11.7 | 3.25 | 28 | 2900 | 2.2 |

40-160(I)B | 10.4 | 2.89 | 22 | 2900 | 1.5 |

40-200(I) | 12.5 | 3.47 | 50 | 2900 | 5.5 |

40-200(I)A | 11.7 | 3.25 | 44 | 2900 | 4 |

40-200(I)B | 10.6 | 2.94 | 36 | 2900 | 3 |

40-250(I) | 12.5 | 3.47 | 80 | 2900 | 11 |

40-250(I)A | 11.6 | 3.22 | 70 | 2900 | 7.5 |

40-250(I)B | 10.8 | 3.0 | 60 | 2900 | 7.5 |

40-250(I)C | 10.0 | 2.78 | 52 | 2900 | 5.5 |

50-100 | 12.5 | 3.47 | 12.5 | 2900 | 1.1 |

50-100A | 11 | 3.05 | 10 | 2900 | 0.75 |

50-125 | 12.5 | 3.47 | 20 | 2900 | 1.5 |

The motor power | Flow quantity Q | lift m | speed r/min | The motor power KW | |

m3/h | l/s | ||||

50-125A | 11 | 3.05 | 16 | 2900 | 1.1 |

50-160 | 12.5 | 3.47 | 32 | 2900 | 3 |

50-160A | 11.7 | 3.25 | 28 | 2900 | 2.2 |

50-160B | 10.4 | 2.89 | 22 | 2900 | 1.5 |

50-200 | 12.5 | 3.47 | 50 | 2900 | 5.5 |

50-200A | 11.7 | 3.25 | 44 | 2900 | 4 |

50-200B | 10.6 | 2.94 | 36 | 2900 | 3 |

50-250 | 12.5 | 3.47 | 80 | 2900 | 11 |

50-250A | 11.6 | 3.22 | 70 | 2900 | 7.5 |

50-250B | 10.8 | 3.0 | 60 | 2900 | 7.5 |

50-250C | 10.0 | 2.78 | 52 | 2900 | 5.5 |

50-100(I) | 25 | 6.94 | 12.5 | 2900 | 1.5 |

50-100(I)A | 22.3 | 6.19 | 10 | 2900 | 1.1 |

50-125(I) | 25 | 6.94 | 20 | 2900 | 3 |

50-125(I)A | 22.3 | 6.19 | 16 | 2900 | 2.2 |

50-160(I) | 25 | 6.94 | 32 | 2900 | 4 |

50-160(I)A | 23.4 | 6.5 | 28 | 2900 | 4 |

50-160(I)B | 21.6 | 6.0 | 24 | 2900 | 3 |

50-200(I) | 25 | 6.94 | 50 | 2900 | 7.5 |

50-200(I)A | 23.5 | 6.53 | 44 | 2900 | 7.5 |

50-200(I)B | 21.8 | 6.06 | 38 | 2900 | 5.5 |

50-250(I) | 25 | 6.94 | 80 | 2900 | 15 |

50-250(I)A | 23.4 | 6.5 | 70 | 2900 | 11 |

50-250(I)B | 21.6 | 6.0 | 60 | 2900 | 11 |

50-315(I) | 25 | 6.94 | 125 | 2900 | 30 |

50-315(I)A | 23.7 | 6.58 | 113 | 2900 | 22 |

50-315(I)B | 22.5 | 6.25 | 101 | 2900 | 18.5 |

50-315(I)C | 20.6 | 5.72 | 85 | 2900 | 15 |

65-100 | 25 | 6.94 | 12.5 | 2900 | 1.5 |

65-100A | 22.3 | 6.19 | 10 | 2900 | 1.1 |

65-125 | 25 | 6.94 | 20 | 2900 | 3 |

65-125A | 22.3 | 6.19 | 16 | 2900 | 2.2 |

65-160 | 25 | 6.94 | 32 | 2900 | 4 |

65-160A | 23.4 | 6.5 | 28 | 2900 | 4 |

65-160B | 21.6 | 6.0 | 24 | 2900 | 3 |

65-200 | 25 | 6.94 | 50 | 2900 | 7.5 |

65-200A | 23.5 | 6.53 | 44 | 2900 | 7.5 |

65-200B | 21.8 | 6.06 | 38 | 2900 | 5.5 |

65-250 | 25 | 6.94 | 80 | 2900 | 15 |

65-250A | 23.4 | 6.5 | 70 | 2900 | 11 |

65-250B | 21.6 | 6.0 | 60 | 2900 | 11 |

65-315 | 25 | 6.94 | 125 | 2900 | 30 |

65-315A | 23.7 | 6.58 | 113 | 2900 | 22 |

65-315B | 22.5 | 6.25 | 101 | 2900 | 18.5 |

65-315C | 20.6 | 5.72 | 85 | 2900 | 15 |

65-100(I) | 50 | 13.9 | 12.5 | 2900 | 3 |

Type no. | Flow quantity Q | lift m | speed r/min | The motor power KW | |

m3/h | l/s | ||||

65-125(I)A | 45 | 12.5 | 16 | 2900 | 4 |

65-160(I) | 50 | 13.9 | 32 | 2900 | 7.5 |

65-160(I)A | 46.7 | 13.0 | 28 | 2900 | 7.5 |

65-160(I)B | 43.3 | 12.0 | 24 | 2900 | 5.5 |

65-200(I) | 50 | 13.9 | 50 | 2900 | 15 |

65-200(I)A | 47 | 13.1 | 44 | 2900 | 11 |

65-200(I)B | 43.5 | 12.1 | 38 | 2900 | 7.5 |

65-250(I) | 50 | 13.9 | 80 | 2900 | 22 |

65-250(I)A | 46.7 | 13.0 | 70 | 2900 | 18.5 |

65-250(I)B | 43.3 | 12.0 | 60 | 2900 | 15 |

65-315(I) | 50 | 13.9 | 125 | 2900 | 37 |

65-315(I)A | 46.5 | 12.9 | 110 | 2900 | 30 |

65-315(I)B | 44.5 | 12.4 | 100 | 2900 | 30 |

65-315(I)C | 41 | 11.4 | 85 | 2900 | 22 |

80-100 | 50 | 13.9 | 12.5 | 2900 | 3 |

80-100A | 44.7 | 12.5 | 10 | 2900 | 2.2 |

80-125 | 50 | 13.9 | 20 | 2900 | 5.5 |

80-125A | 45 | 12.5 | 16 | 2900 | 4 |

80-160 | 50 | 13.9 | 32 | 2900 | 7.5 |

80-160A | 46.7 | 13.0 | 28 | 2900 | 7.5 |

80-160B | 43.3 | 12.0 | 24 | 2900 | 5.5 |

80-200 | 50 | 13.9 | 50 | 2900 | 15 |

80-200A | 47 | 13.1 | 44 | 2900 | 11 |

80-200B | 43.5 | 12.1 | 38 | 2900 | 7.5 |

80-250 | 50 | 13.9 | 80 | 2900 | 22 |

80-250A | 46.7 | 13.0 | 70 | 2900 | 18.5 |

80-250B | 43.3 | 12.0 | 60 | 2900 | 15 |

80-315 | 50 | 13.9 | 125 | 2900 | 37 |

80-315A | 46.5 | 12.9 | 110 | 2900 | 30 |

80-315B | 44.5 | 12.4 | 100 | 2900 | 30 |

80-315C | 41 | 11.4 | 85 | 2900 | 22 |

80-350 | 50 | 13.9 | 150 | 2900 | 55 |

80-350A | 44.5 | 12.4 | 142 | 2900 | 45 |

80-350B | 41 | 11.4 | 135 | 2900 | 37 |

80-100(I) | 100 | 27.8 | 12.5 | 2900 | 5.5 |

80-100(I)A | 89 | 24.7 | 10 | 2900 | 4 |

80-125(I) | 100 | 27.8 | 20 | 2900 | 11 |

80-125(I)A | 89 | 24.7 | 16 | 2900 | 7.5 |

80-160(I) | 100 | 27.8 | 32 | 2900 | 15 |

80-160(I)A | 93.5 | 26.0 | 28 | 2900 | 11 |

80-160(I)B | 86.6 | 24.1 | 24 | 2900 | 11 |

80-200(I) | 100 | 27.8 | 50 | 2900 | 2 |

80-200(I)A | 93.5 | 26.0 | 44 | 2900 | 18.5 |

80-200(I)B | 87 | 24.2 | 38 | 2900 | 15 |

80-250(I) | 100 | 27.8 | 80 | 2900 | 37 |

80-250(I)A | 93.5 | 26.0 | 70 | 2900 | 30 |

80-250(I)B | 87 | 24.2 | 60 | 2900 | 30 |

80-315(I) | 100 | 27.8 | 125 | 2900 | 75 |

Type no. | Flow quantity Q | lift m | speed r/min | The motor power KW | |

m3/h | l/s | ||||

80-315(I)A | 95 | 26.4 | 113 | 2900 | 55 |

80-315(I)B | 90 | 25 | 101 | 2900 | 45 |

80-315(I)C | 82 | 22.8 | 85 | 2900 | 37 |

100-100 | 100 | 27.8 | 12.5 | 2900 | 5.5 |

100-100A | 89 | 47 | 10 | 2900 | 4 |

100-125 | 100 | 27.8 | 20 | 2900 | 11 |

100-125A | 89 | 24.7 | 16 | 2900 | 7.5 |

100-160 | 100 | 27.8 | 32 | 2900 | 15 |

100-160A | 93.5 | 26.0 | 28 | 2900 | 11 |

100-160B | 86.6 | 24.1 | 24 | 2900 | 11 |

100-200 | 100 | 27.8 | 50 | 2900 | 22 |

100-200A | 93.5 | 26.0 | 44 | 2900 | 18.5 |

100-200B | 87 | 24.2 | 38 | 2900 | 15 |

100-250 | 100 | 27.8 | 80 | 2900 | 37 |

100-250A | 93.5 | 26.0 | 70 | 2900 | 30 |

100-250B | 87 | 24.2 | 60 | 2900 | 30 |

100-315 | 100 | 27.8 | 125 | 2900 | 75 |

100-315A | 95 | 26.4 | 113 | 2900 | 55 |

100-315B | 90 | 25 | 101 | 2900 | 45 |

100-315C | 82 | 22.8 | 85 | 2900 | 37 |

100-100(I) | 160 | 44.4 | 12.5 | 2900 | 11 |

100-125(I) | 160 | 44.4 | 20 | 2900 | 15 |

100-125(I)A | 140 | 39 | 17 | 2900 | 11 |

100-160(I) | 160 | 44.4 | 32 | 2900 | 22 |

100-160(I)A | 140 | 39 | 28 | 2900 | 18.5 |

100-200(I) | 100 | 44.4 | 50 | 2900 | 37 |

100-200(I)A | 140 | 39 | 45 | 2900 | 30 |

100-200(I)B | 100 | 27.8 | 40 | 2900 | 22 |

100-250(I) | 160 | 44.4 | 80 | 2900 | 55 |

100-250(I)A | 140 | 39 | 72 | 2900 | 45 |

100-250(I)B | 100 | 27.8 | 65 | 2900 | 37 |

100-350 | 100 | 27.8 | 150 | 2900 | 90 |

100-350A | 87 | 24.2 | 142 | 2900 | 75 |

100-350B | 82 | 22.8 | 135 | 2900 | 55 |

125-100 | 160 | 44.4 | 12.5 | 2900 | 11 |

125-100A | 143 | 39.7 | 10 | 2900 | 7.5 |

125-125 | 160 | 44.4 | 20 | 2900 | 15 |

125-125A | 143 | 39.7 | 16 | 2900 | 11 |

125-160 | 160 | 44.4 | 32 | 2900 | 22 |

125-160A | 150 | 41.7 | 28 | 2900 | 18.5 |

125-160B | 138 | 38.3 | 24 | 2900 | 15 |

125-200 | 160 | 44.4 | 50 | 2900 | 37 |

125-200A | 150 | 41.7 | 44 | 2900 | 30 |

125-200B | 138 | 38.3 | 37.5 | 2900 | 22 |

125-250 | 160 | 44.4 | 80 | 2900 | 55 |

125-250A | 150 | 41.7 | 70 | 2900 | 45 |